In this first section, Mr Norris is describing his design experience from the Second World War onwards.

…buildings there that were bombed by the Germans, and the outcome was that the company was moved into a huge geographic area, so that if one part of it was bombed, the rest could still carry on. They took over all sorts – bus depots, large buildings – and assembly was spread around. The headquarters was a huge big country house, and the grounds, and after the war that was the head office of Vickers Amstrong Supermarine. I wanted to get into the drafting side, and I thought, “well, I really know nothing about the practical side of it,” so I did a five-year apprenticeship as an aircraft woodworker, which was really more like toolmaking and patternmaking. We made the press materials by hand from a wood material called Jabrol, which was very hard. We were designing and building the prototype jet fighters.

So, I did the five years’ apprenticeship, and I stayed in the drawing office until the company decided they were going to move out of Hearstley Park and go to a town called Bournemouth, where the company had a large airfield. I didn’t want to do that because I’d just got married and bought a house. One of my colleagues said that there’s a company on the outskirts of Portsmouth making aviation stuff. Well, the drawing office, they were doing work on one of the four-engined jet bombers. So we both went to that business, and I suppose I spent a bit less than a year there. The contract finished and they closed the drawing office! They had a big area, a big workshop, doing all sorts of engineering and assembly work on aircraft, but the drawing side was just shut down.

I then came back to Southhampton, to a company called Air Service Training, at Hamble, and one of my ex-Supermarine colleagues was working there, and they were doing a rocket project. So I became a rocket scientist on Blue Steel, which was a rocket carried by a four-jet bomber with a nuclear warhead. I worked on the rocket project, and we finished it, and one day the boss walked into the office of 300 of us. He walked into the middle, stuck his arms up, and said “everybody behind me, pack up and go home, and we’ll send your wages on to you. We’ve lost out on the jet helicopter project.” We’d put a tender in to do a jet helicopter, and we lost it. That was the end of the development side of Air Service Training. In six weeks everybody had been made redundant; they’d sold all of the equipment and we were all on the street!

In those days we worked on drawing boards with a T-square, and the only computer device was on a dais in the middle of the floor, and it did four functions – division, multiplication, subtraction and so on. Anyway, I bought up one of the drawing boards and T-squares, which I’ve actually got with me now in Feilding still. I looked around for a job and thought, “there’s no future in aviation”. I’d heard of the Dimplex company, so I rang them up and talked to the development manager. He said “oh, I’m looking for a chief draughtsman, you’d better come and see me.” So I went and met with him and got the job of chief draughtsman, and spent ten years with them designing a whole range of electric heating appliances.

The thing that the company had kicked off was the oil-filled electric radiator, which was quite big business. We also made a water version of it, a hot water version, because in the UK, even to this day, central heating – domestic central heating – with hot-water radiators is still probably the biggest form of heating.

So anyway, we got involved in the early stages of infrared heating – those heaters that were up on the wall, and had a beam – so designed a range of those. Quite interesting, all sorts of things. That brought me to Dreamland to design the blanket.

And then on to New Zealand.

And then on to New Zealand, yeah!

Designing jet bombers to electric blankets, that’s a bit of a jump.

Well, a bit of a difference, and interesting. The process is essentially much the same: if you’ve got to design something, you’ve got to work it out and draw it. But one of the skills it did give me was to draw everything complete.

Now, in the building industry in New Zealand, we have all sorts of people complaining about their new house, that there’s something wrong with it. And I think the major problem seems to be that architectural people do not do a full drawing design, which we had to. Every last nut and bolt on an aeroplane – or a rocket or whatever – had to be carefully designed and drawn and specified; there was no possible chance of anything going wrong. Within the industry itself, you had to be ultra-careful; all of our tradespeople had a board, with our tools mounted on the board and painted black and white, so that if a tool was missing off the toolboard, you had to find it before you could do anything and leave, because a single screwdriver or spanner left in an aeroplane can cause it to crash.

So the whole industry, everything had to be right and be safe and be fully designed, fully engineered in every respect. You couldn’t afford a single mistake. I’ve found that a very useful discipline, which whever I’ve worked I’ve tried to make people do the same

That transfers over well to designing electric frypans

Yes!

I was working in the UK with Dreamland Appliances, making electric blankets, and the boss of the company gave a license to a firm in New Zealand, and they had hired a chap to be their works manager in the UK, and he came and spent some time with us. I had the job of showing him how to make electric blankets. It was really quite difficult, and I said to the boss, “look, really we need someone to go down there and show them what to do”. So he said, “would you do it?”

I was working in the UK with Dreamland Appliances, making electric blankets, and the boss of the company gave a license to a firm in New Zealand, and they had hired a chap to be their works manager in the UK, and he came and spent some time with us. I had the job of showing him how to make electric blankets. It was really quite difficult, and I said to the boss, “look, really we need someone to go down there and show them what to do”. So he said, “would you do it?”

I had a two-year contract with Ralta in Palmerston North to set up the factory, train the staff and get everything done. I did that, and I spent about three years with Ralta. I was having problems hiring staff for the tool room or the drawing office; I had to bring them in from the UK. So I thought I’d better go and train a few. I talked with the principal of what was in those days the Palmerston North Technical Institute, and he said “oh, great, we need somebody who could be our liaison officer to visit high schools and talk to them about tertiary education”, because in those days we only had a polytech in Wellington, Palmerston, Hamilton and Auckland. So I covered an area from New Plymouth to Napier, down to Otaki and across to the east coast, and I used to visit every high school there and talk to them about tertiary education.

Your first work with Ralta was making electric blankets?

You see, Ralta had been making blankets with the old-fashioned method – it was called “tunnel-cloth” – where two pieces of fabric were machined together in a machine process. As the fabric was woven it was also machined. There were two pieces with gaps between the rows of sewing, and you cut a blanket shape and put it onto a table. You had a woman on each side and had a long steel rod, and the element wire was attached to the end of the rod, and the rod was poked through the first channel, all the wire was pulled through, then it was poked back [through] the next one; it took ages to make a single blanket! You had one length of cable – heating element wire – which went in one side and came out the other, you’d join them together with a lead and that was your blanket. Very expensive, very slow process.

Now, a guy at Dreamland Appliances in the UK invented a process of welding fabric together. The fabric was specially made: it had a plastic film on one side, and you put the two plastic surfaces together, and with a high-frequency welding machine you could make a permanent bond of the cloth. The setup was: we had a large table with a welding machine at the end of a conveyor belt. You first of all spiked the one side the cloth on, then the element was already made up in length, and that was put around pins. Then the second layer of cloth was put on top, it went into the welding machine, and you ended up with a blanket completely welded together. All you had to do was trim the edges and sew them, and join the supply cables. I had to set up the whole setup in Ralta. We got a single welding machine made because they they thought that would be sufficient to meet their demand, and the welding machine was built in Auckland by a specialist company. I had to train the staff how to work and design the products for them. I spent about three years with them and then moved on.

Did Ralta at that time also do the jugs and the pans that you mentioned before?

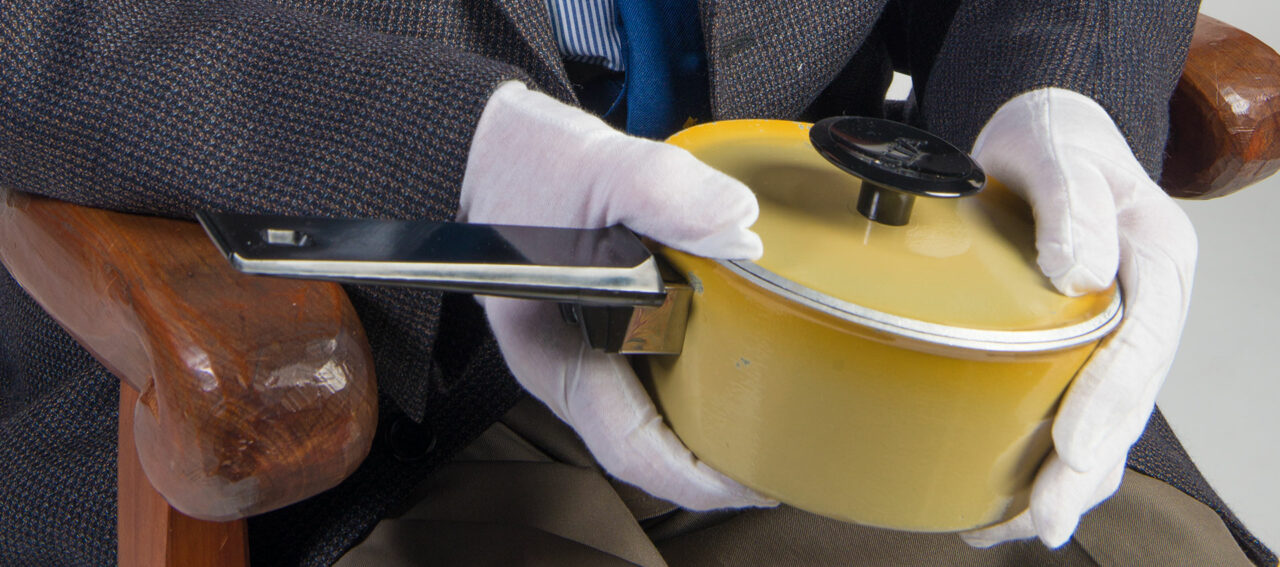

Oh yes! Ralta did a range. It started off with blankets and electric frypans, and the electric frypan was originally subcontracted to Wellington, because the company there used to cast the base, and the element was included in the base. When we decided we would get into a range of pots and pans, we bought two special metal spinning machines from Germany, which were completely automatic, and were then able to make a whole range of electric pots and frypans and so forth.

A lot of the stuff was subcontracted and just sold by Ralta with their name on. For example we had a little battery clock which folded up into a case so you could take it as an alarm clock. We made a small plastic fan because, again, Ralta had got a number of plastic moulding machines, and the early ‘70s was the beginning of the age when we moved from things made of metal to things made of plastic. Plastic jugs, for example.

Somebody had the bright idea that we’d make stereos. We had a joiner who came to set the whole thing up and run it, and when it was closed down he joined the polytech as one of the staff there. The stereo thing, I think it only lasted about a year or so and then it just quietly folded up because there was no market for them – a classic example of rather than seeing what the market wanted and what the competition were offering, we just plunged into it, and it was a bit of a disaster.

What would the design process of one of these pans be like? You designed some of them?

Yes, well, one of the directors would see an appliance somewhere and say “oh, I think we ought to make this”, you see. Now, we had a chap who was the sort of works director, named Bill Burnby, and he was sent off to Germany to go and visit a trade fair. The Germans have two or three really big trade fairs each year. He came back with a bread toaster, a two-slice bread toaster – a well-known German company made it. They brought it into the office one day and said “we’re going to make this toaster”, and what was different about it was you dropped the bread in the top, and when it was cooked there were hinged arms that carried the bread, and they came up like this, so the bread poked out of [the device], and you could see it and take it out.

So they brought this sample in, and with my office staff we took it completely to pieces, examined every part of it, and looked at the process. The Germans had obviously used a fairly sophisticated process of presswork, which we didn’t have. We were told “this is what they’re selling, so therefore you’ve got to copy it exactly and you can’t change anything”. I pleaded, “let’s have a few basic changes”, but no, no, no, that’s got to be. So I took it to the tool room and talked to the people there, and they said “well, they’re all individual parts, we’ll have to make individual tools for everything, and it’s going to be a lot of work”.

So we made it, and all these different pieces came out and most of them had sharp edges, and we had teams of eight or nine ladies assembling these, and without a word of a lie, they had all ten fingers and thumbs bound up with bandages from where they’d cut themselves, and it was absolutely hopeless. We carried on making it for a bit and then stopped, because what we discovered was, it was a prototype that Bill had been given at this trade fair. The Germans had never made it at all as a production model. They changed to something else, and we ended up making a conventional pop-up toaster which was very simple and straightforward.

It was a classic of every mistake that could be made was deliberately made, because the management said “you can’t change anything, because this is what the Germans have made”.

So all of that effort, all for nothing in the end

Yeah! So anyway, that was just one example. A number of things were designed – usually if something was brought in and they wanted a copy of it, we would design it to suit our setup and our type of equipment so that we could mould it with our machines.

How many of them would you make a year?

It would be many thousands. The blanket setup, for example: with only one welding press there was a limit to how many blankets could be made. But they carried on for a long time. After I’d left, the company was sold to Sunbeam and [they] got the Chinese to come in and make the blankets, so the production went to China, just as in the UK Dreamland subcontracted the blankets to China for manufacturing. All they did was retain a marketing arm, selling the stuff as a Dreamland blanket, but it was no longer made in the UK. Or in New Zealand for that matter. And that was just the way of life really, because the Chinese offered such better prices. All you needed was a stores setup and a sales setup and you were in business!

A lot of people might find it odd that something from the ’80s is in a museum, but you don’t see them anymore, do you. They’ve just disappeared.

Well, no. We’ve changed a great deal, and they’re worth keeping, they’re worth putting in a museum.

Images by Udo von Mulert